The hot-rolled carbon steel plate stands out for its strength, cost efficiency, and adaptability, serving as a reliable choice for industrial and infrastructure projects. It streamlines design-to-execution workflows, empowering clients to achieve efficiency and durability!

High Strength & Structural Integrity: Hot-rolled carbon steel coil offers superior tensile strength and durability, ideal for demanding industrial and construction applications. Cost-Effective Production: Manufactured through high-temperature rolling, it reduces energy consumption and production costs while maintaining consistent quality.

Carbon steel pipe is a versatile and widely utilized industrial product, renowned for its strength, durability, and cost - effectiveness. Manufactured primarily from carbon steel, which contains a small percentage of carbon (usually between 0.05% and 2.1%) along with trace amounts of other elements, these pipes are produced through various methods such as seamless extrusion or ERW (Electric Resistance Welding).

Galvanized steel pipe, also known as galvanized pipe, is divided into two kinds of hot-dip galvanized pipe and Electro galvanized pipe. The hot-dip galvanized layer is thick, the coating is uniform, the adhesion is strong, and the service life is long.

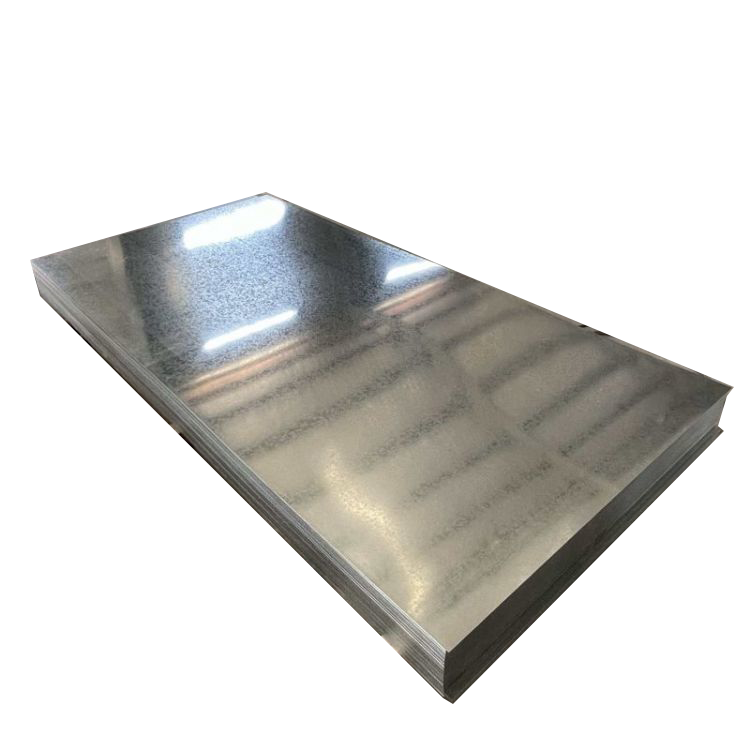

Galvanized steel sheet is a type of steel that has been coated with a layer of zinc through a chemical process. This zinc coating provides several key benefits, making it a popular choice in various industries.

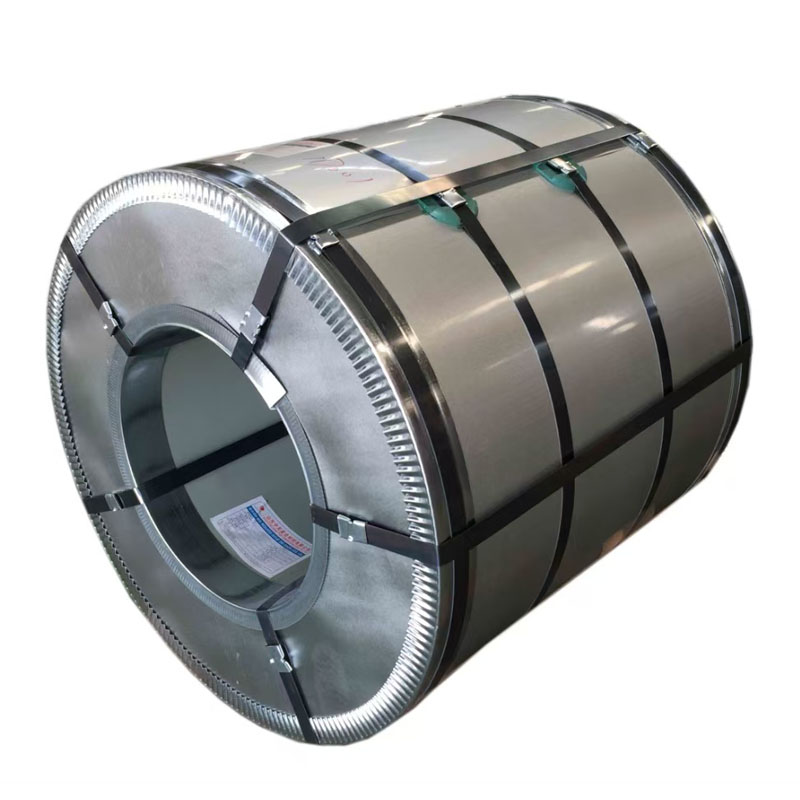

Galvanized steel coil is a highly engineered and widely utilized material, produced by coating a continuous sheet of steel with a protective layer of zinc through either hot - dip galvanizing or electro - galvanizing methods. Rolled into compact coils, this product combines the inherent strength of steel with the superior corrosion - resistance of zinc, making it a cornerstone in countless industrial, commercial, and residential applications.

Galvanized steel pipe features excellent corrosion resistance due to its zinc coating, ensuring long-lasting durability in various environments. t offers high strength and structural stability, suitable for construction, plumbing, and industrial applications.

Our Galvanized steel wire features an innovative dual - layer protection mechanism. The inner layer of high - carbon steel provides the foundation for superior strength, while the outer zinc coating, applied through a state - of - the - art hot - dip galvanization process, forms an impenetrable shield.

ribbed steel bar, as a core foundation material in the field of construction, has become a reliable guarantee for various engineering constructions due to its excellent performance and wide applicability.

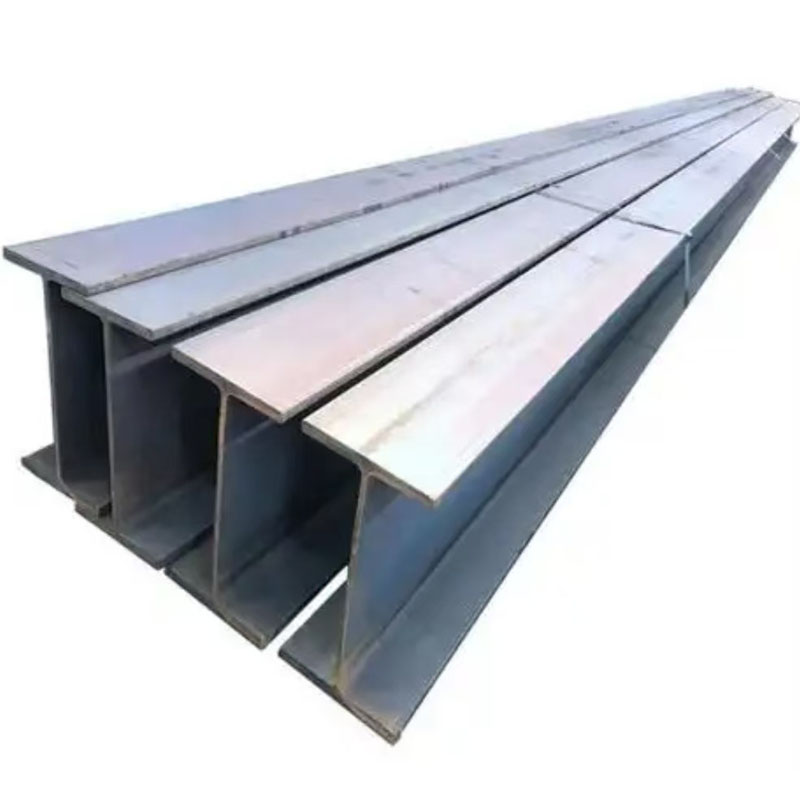

H-beam offers high strength and stability, with yield strengths ranging from 235MPa to 460MPa and tensile strengths from 370MPa to 630MPa. It can adapt to complex and variable stress environments, ensuring the safety and durability of building structures. With a wide range of specifications, the height of H-beam varies from 100mm to 1200mm, and the width of flanges, thickness of webs,.

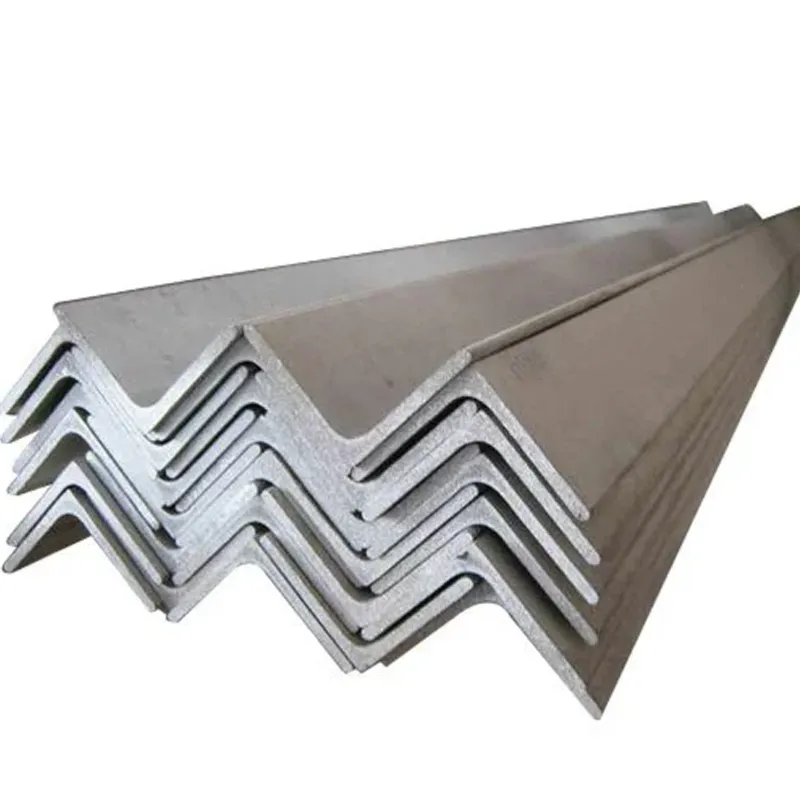

The galvanized angle iron is corrosion-resistant and can be used for a long time in a humid environment. Made of high-quality steel, the angle iron has high mechanical strength and can withstand heavy loads. The angle iron is reasonably designed, easy to install, and can quickly complete the grounding work.

Channel steel can be used as the main beam of the rack. The rack uses channel steel as the main body, and the middle reinforcement plate is welded together to ensure the stability of the structure. For example, in the rack construction of some industrial equipment, this structural design can withstand greater weight and external impact.

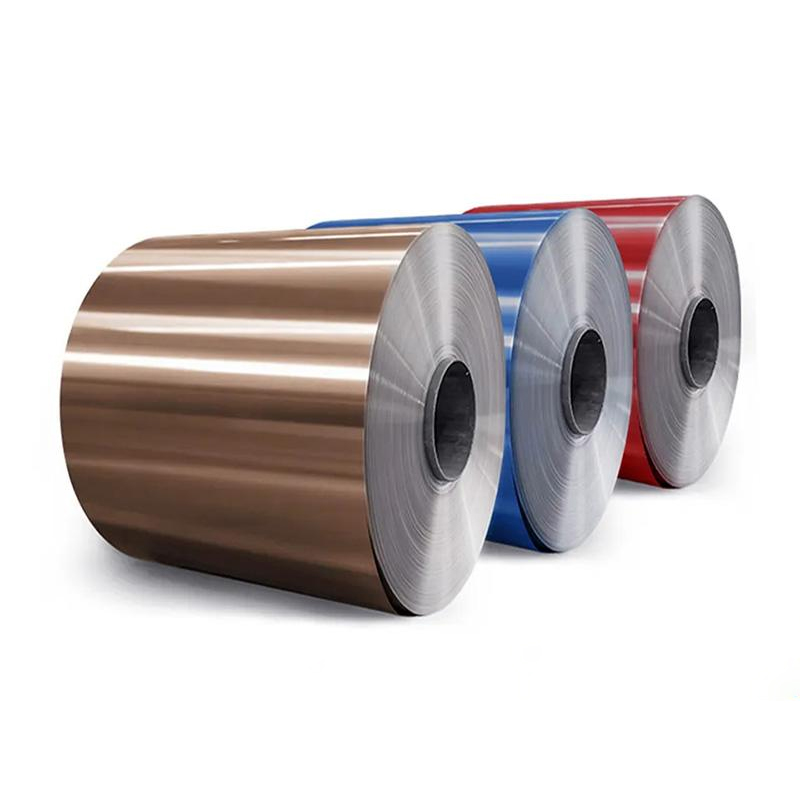

The Color-coated sheet is a premium, multi-functional material that seamlessly combines durability, aesthetic appeal, and cost - efficiency. It starts with a robust galvanized or galvalume steel substrate, which provides inherent protection against rust and corrosion through a sacrificial zinc or zinc - aluminum layer.

Color coated steel coil is a high-performance building material renowned for its durability, aesthetic versatility, and corrosion resistance. Crafted from a base layer of galvanized or galvalume steel, it undergoes a specialized coating process to apply a vibrant, protective finish.

It is corrugated, which increases the strength and rigidity of the sheet, making it more stable when subjected to pressure and weight. It is treated with processes such as galvanizing and color coating. The galvanizing process can improve the corrosion resistance of the sheet, and the color coating gives the sheet rich colors and beautiful appearance, while further enhancing its protective performance. There are many surface treatment methods, such as anti-rust paint, varnish, galvanizing, 3LPE, 3PP, zinc oxide yellow primer, zinc phosphate primer, etc., which can be selected according to customer requirements.

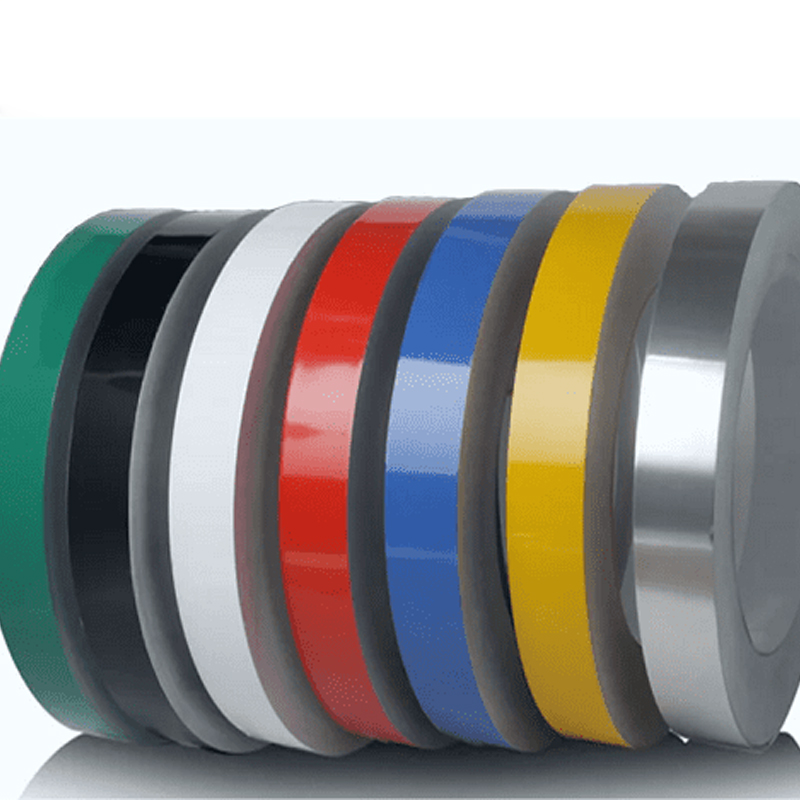

The Color-coated strip is a high-performance, versatile material designed to meet the diverse needs of modern manufacturing and construction. Crafted with a galvanized or galvalume steel substrate, it offers robust protection against corrosion, ensuring durability even in harsh environments.